la hardness micro deval test|micro deval vs la abrasion : exporters Hardness • Hardness is the aggregate’s resistance to abrasion (wear) • Hardness is an important property for aggregates in pavement surfaces • Tested by LA Abrasion or Micro Deval

Business listings of Class B Autoclave, Autoclave B manufacturers, suppliers and exporters in Chennai, Tamil Nadu along with their contact details & address.

{plog:ftitle_list}

Portable, Top-loading Autoclaves With Advanced Safety and User-Friendly Features. Space-saving design with lid opening upward. Programmable auto-start for initiating a cycle up to 1 .

micro deval vs la abrasion

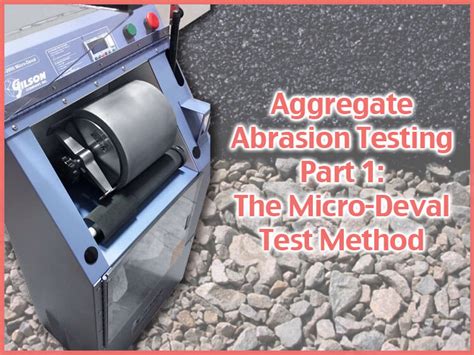

Abrasion testing measures the relative quality and durability of mineral aggregates when .Micro-Deval Test: an Alternative to L.A. Abrasion Wu et al. (1998 [2] ) found the Micro-Deval apparatus to be the only commonly used test that had adequate predictive abilities concerning toughness and abrasion resistance.Abrasion testing measures the relative quality and durability of mineral aggregates when subjected to abrasion and impact. There are two popular tests widely used today: Los Angeles (L.A.) Abrasion Test and the Micro-Deval Test.Values derived from both the Micro Deval and the L.A. Abrasion tests offer information about the performance of aggregate in use. This testing offers insight into how asphalt and concrete aggregates will stand up to wear and tear over time.

One widely recognized method of testing the toughness and abrasion resistance of these materials is the Los Angeles (L.A.) Abrasion Test. This detailed exploration will unwrap the complexities, applications, limitations, and an alternative approach to this renowned test.Hardness • Hardness is the aggregate’s resistance to abrasion (wear) • Hardness is an important property for aggregates in pavement surfaces • Tested by LA Abrasion or Micro Deval For example, slag and certain limestones often show high LA Abrasion loss but perform well on-site. For additional insight, the Micro-Deval test can be used. This test is similar to the LA Abrasion test but employs a smaller drum and spheres.

The Los Angeles abrasion test (LA abrasion) is the North American standard for testing toughness (resistance to abrasion and degradation [1]) of construction aggregate or gravel and its suitability for road construction. A comprehensive literature review study has been conducted to establish the relationship between geological parameters (mineralogy, grain size, crystal size, grain shape, and porosity) of rocks and two most common tests: the Los Angeles (LA) test . Tests of resistance to wear and fragmentation are performed in the micro-Deval apparatus (the M DE/DS test) and in the Los Angeles drum (the LA test). Comparative tests demonstrated that the M DE/DS test is more effective than the LA test, as . The two most common mechanical tests used to investigate the performance of aggregates are the Los Angeles (LA) and micro-Deval (MD) tests. This study reviewed the geological parameters.

Micro-Deval Test: an Alternative to L.A. Abrasion Wu et al. (1998 [2] ) found the Micro-Deval apparatus to be the only commonly used test that had adequate predictive abilities concerning toughness and abrasion resistance.Abrasion testing measures the relative quality and durability of mineral aggregates when subjected to abrasion and impact. There are two popular tests widely used today: Los Angeles (L.A.) Abrasion Test and the Micro-Deval Test.Values derived from both the Micro Deval and the L.A. Abrasion tests offer information about the performance of aggregate in use. This testing offers insight into how asphalt and concrete aggregates will stand up to wear and tear over time.

One widely recognized method of testing the toughness and abrasion resistance of these materials is the Los Angeles (L.A.) Abrasion Test. This detailed exploration will unwrap the complexities, applications, limitations, and an alternative approach to this renowned test.Hardness • Hardness is the aggregate’s resistance to abrasion (wear) • Hardness is an important property for aggregates in pavement surfaces • Tested by LA Abrasion or Micro Deval

For example, slag and certain limestones often show high LA Abrasion loss but perform well on-site. For additional insight, the Micro-Deval test can be used. This test is similar to the LA Abrasion test but employs a smaller drum and spheres.

The Los Angeles abrasion test (LA abrasion) is the North American standard for testing toughness (resistance to abrasion and degradation [1]) of construction aggregate or gravel and its suitability for road construction.

A comprehensive literature review study has been conducted to establish the relationship between geological parameters (mineralogy, grain size, crystal size, grain shape, and porosity) of rocks and two most common tests: the Los Angeles (LA) test .

Tests of resistance to wear and fragmentation are performed in the micro-Deval apparatus (the M DE/DS test) and in the Los Angeles drum (the LA test). Comparative tests demonstrated that the M DE/DS test is more effective than the LA test, as .

micro deval testing

jura water hardness test strip

The Arizona State University (ASU) Autoclave Safety Manual is a resource for information, guidelines, policies, and procedures enabling and encouraging staff using autoclaves to work .Autoclave Engineers offers universal safety heads in three series compatible in orifice size and maximum pressure rating with Autoclave Low Pressure, Medium Pressure and High Pressure .

la hardness micro deval test|micro deval vs la abrasion